Service

Découpe couteau basé à Toulouse

Price of the Service

Category of the Service

Company website

Our recommended products and services

-

-

We support you in the production of individual and serial products As a contract manufacturer, we also support you in the production and processing of metal goods – regardless of whether the ordered goods are individual or series production. In order to guarantee the required quality and precision in the manufacturing processes, we have at our disposal, in addition to decades of professional know-how, a modern, CNC-controlled machine park: including a laser cutting machine, various bending benches and a fully automatic swivel bending center. In addition, we have many years of experience in the use of welding processes (TIG & MAG). Large parts of the post-processing of the manufactured components can also be carried out on our premises, including: Coatings Painting work as well as pickling

-

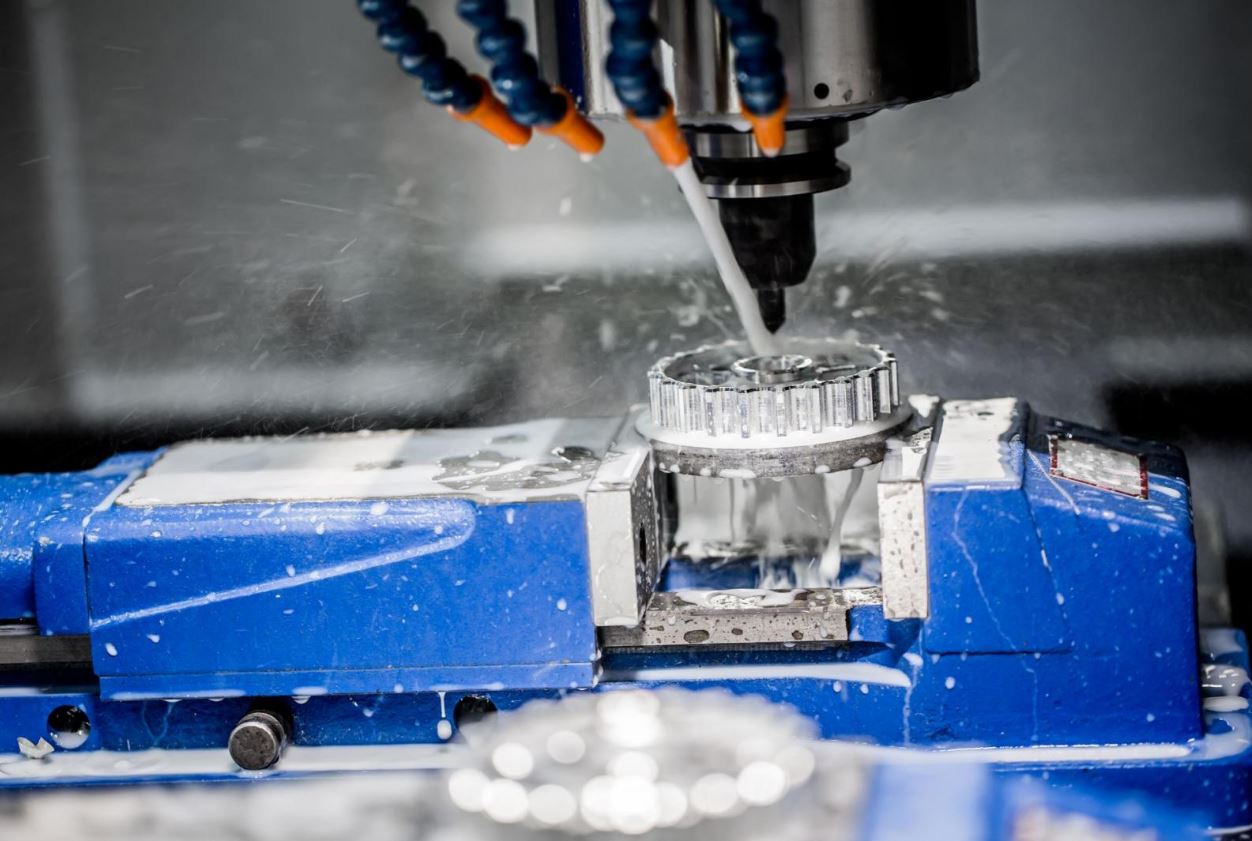

Cutting is a fast and efficient way of producing workpieces using our machines. We can offer cutting in the form of turning, drilling or milling of various metals, on both cut and forged blanks. We can produce advanced workpieces with high tolerance requirements. These are usually run in large batches, primarily in one of our transfer machines, but also in multitasking, horizontal and vertical. We deliver everything from small to large workpieces, always with the same high quality.

-

PLASMA CUTTING Plasma cutting is a process in which the sheet material is cut with a very hot air stream that melts the material in the joint. The air flow is heated by passing an electric arc and its temperature is 15000-20000 ° C, which causes atoms and electrons to be separated into a plasma. Plasma cutting can be used for all types of materials. Steel can be cut into wall thicknesses of up to approx. 50 mm, and aluminum of up to approx. 200 mm. For steel cutting, we use ordinary air. One of the advantages of plasma cutting is that the high cutting speed provides little heating, which means that only small or minimal deformations occur.

-