Product

OJ Drives

Based on more than 50 years in the HVAC business, OJ Electronics has developed drives for the ventilation segment through three decades. Our combination of high product quality and extensive ventilation application know-how continues to bring innovative, dependable drives to discerning customers worldwide.

The OJ Drives® programme contains the DV and DRHX ranges, which allows you to find an OJ drive for virtually any ventilation application – including air handling units, livestock ventilation, chiller fans, rooftop fans, plug fans, box fans and rotary heat exchangers.

Price of the Product

Category of the Product

Company website

Our recommended products and services

-

-

Product Model: HLYZ The Universal Casing Running System ensures uniform and proper connection of the casing string by indicating the exact torque applied to each joint when running casing or tubing. Our high-torque measuring device helps reduce the failure of drill collars and tool joints due to improper installation. This system includes a 6-inch torque indicator with a bracket, a standard 25-foot hose, and a tension weighing sensor. The convenient installation design allows the gauge to be mounted on the driller’s console, weight indicator box, or installed separately. Product Attributes: • 6-inch dial face with color-customizable markings • Standard capacity up to 30,000 pounds • Available in box or panel mounting styles • Metric and Imperial dual-range options • Adjustable target pointer can be set to the desired capacity, allowing the driller to work to a clear mark Advantages: • Easily visible 6-inch dial face, clear from a distance • Easily installed in various locations: driller’s console, weight indicator box, or standalone • Liquid-filled indicator, reducing impact, vibration, and corrosion • Adjustable damper: allows smooth pointer movement under intense conditions • Tension cylinder: includes a fully machined stainless steel piston rod, providing extra protection • for harsh marine environments, ensuring a longer service life and minimal maintenance. Procurement Parameters: • Required range of the torque gauge • Hose length • Type of torque gauge

-

Product Model: ELYB1560 The high-precision electronic pressure gauge is designed to withstand the extreme operating conditions of the drilling platform, specifically for pumping, cementing, and choke measurement operations. This 6-inch instrument provides a familiar analog dial along with a digital readout to ensure accuracy and reliability. Product Attributes: 6-inch dial face with color-customizable logos Standard capacity up to 30,000 psi Dual scales on the dial with metric equivalents in kg/cm⊃2;, MPa, kPa, and bar Digital readout measurement units selectable among PSI, MPa, kPa, and bar LED backlight with user-adjustable settings Adjustable high/low alarm settings via relay Overpressure shutdown function Input voltage: 12-36 VDC Available signal inputs: 4-20 mA, 0-5 VDC, 0-10 VDC, and 3mV/V Intrinsic safety option available (requires additional barrier) Zeroing is a simple button procedure Advantages: The dial face is clearly visible and can be read from a distance Both analog and digital dial readings allow users to quickly check pressures from a familiar distance and obtain precise digital readings up close User-adjustable LED backlight provides full readability in daylight or at night The overpressure shutdown function automatically shuts down the pump when set points are reached Users can easily input commands using a user-friendly interface with a keyboard Special connectors can be provided upon request Optional splitter boxes are available for multiple instrument input/output signal devices Procurement Parameters: Pressure range Signal input requirements Connector type Cable length (if required)

-

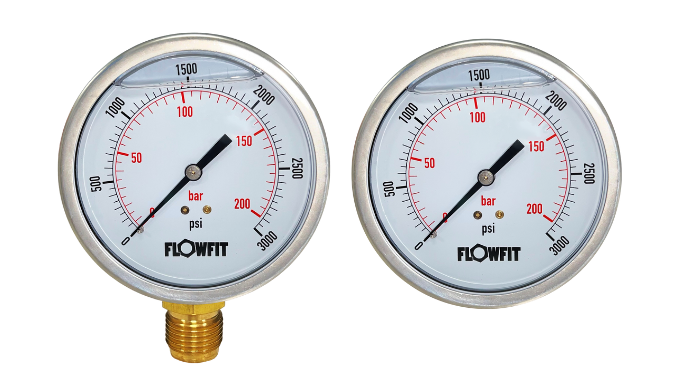

Pressure Gauges are an essential component of any hydraulics system. They act as a means of understanding the pressure that is currently being exhibited within the system. This information is necessary to the continued effectiveness of the entire system. A low pressure reading may mean that certain components of the system are working improperly or not working at all. A high pressure reading might also indicate that components are working improperly, but on the other end of the scale – they are producing too much pressure. In the event of your system suffering too high a pressure reading, it is in danger of damaging itself due to certain parts being unable to cope with the extreme pressures. There is even the risk of an explosion! A Wide Range Of Hydraulic Pressure Gauges The most common design of hydraulic pressure gaugeis the Bourdon-tube gauge. The basic principle of the pressure gauge has not changed since the invention of the Bourdon-tube, more than a century ago, but different gauges are available to meet the different criteria of individual Hydraulic Systems. Dry/Pneumatic Pressure Gauges – These types of Gauges are designed for usage in non-corrosive environments, or where they are unlikely to be shaken or exposed to continual or strong vibrations. Glycerine Filled Pressure Gauges – These types of Hydraulic Pressure Gauges are filled with liquid, Glycerine, which dampens the effects of shock and vibration on the gauge. This liquid also provides continuous lubrication which works to extend the life-cycle of the gauge. Both of these designs of Pressure Gauges are available with different specifications attached. For example, these gauges can be lower or rear mounted depending upon the set up of the system. They are available with solitary or dual-dimensional scales in a variety of calibrations, including psi and bar. They range from 40mm to 100mm in size, and are treated to suit different temperatures, and different scales of pressure. For more information, or for advice regarding which Hydraulic Pressure Gauges are right for your system, be sure to contact us on 01584 876 033, or email us at sales@flowfitonline.com.

-